Diagnostic and safety equipment

When maintaining or troubleshooting a laser system, the proper tools can make the difference between a straightforward task, skillfully performed, and frustration. To help our customers make the most of their valuable time, Directed Light carries an array of practical diagnostic and safety equipment including protective eyewear, autocollimators, laser power meters and probes, beam imaging equipment, HeNe alignment lasers and RF instruments.

Remember, industrial laser systems can be dangerous. Improper service procedures can lead to serious injury or death. Industrial lasers should be serviced only by trained technicians.

Autocollimators

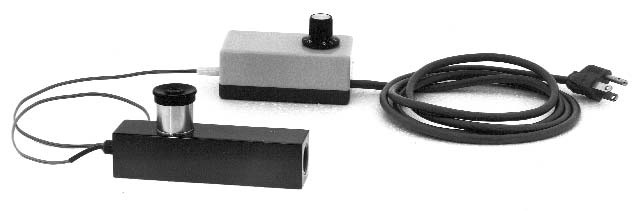

Autocollimators are used to align the optical components on an Nd:YAG laser rail. The autocollimator system consists of an illumination bulb and power supply, a projection lens system and a viewing eyepiece. After ensuring that the laser system is completely shut off, the technician uses the autocollimator to project a beam of light down the optical path, through the Nd:YAG rod and the front and rear mirrors. Each optical surface will send a reflection back to the autocollimator. These reflections can be viewed through the eyepiece. The technician aligns or “tunes” the laser rail by mechanically adjusting each optical component until the reflected spots are overlapping. Once the reflections are overlapping, the system is ready to lase. Fine tuning for best mode and peak power can then be performed with an imaging plate and power meter.

Autocollimators are used to align the optical components on an Nd:YAG laser rail. The autocollimator system consists of an illumination bulb and power supply, a projection lens system and a viewing eyepiece. After ensuring that the laser system is completely shut off, the technician uses the autocollimator to project a beam of light down the optical path, through the Nd:YAG rod and the front and rear mirrors. Each optical surface will send a reflection back to the autocollimator. These reflections can be viewed through the eyepiece. The technician aligns or “tunes” the laser rail by mechanically adjusting each optical component until the reflected spots are overlapping. Once the reflections are overlapping, the system is ready to lase. Fine tuning for best mode and peak power can then be performed with an imaging plate and power meter.

Laser Power Meters

Power meters are extremely useful instruments for anyone operating, troubleshooting or tuning a laser system. With a properly selected detector head, a power meter can be used to continuously monitor the output power or per-pulse energy in a laser beam. This continuous use capability is very helpful when tuning a laser for peak output power. Displays are available with analog or digital readout. The more sophisticated consoles can provide a wide range of real time and recorded data on the laser’s performance.

Ophir laser power meters

Protective eyewear

Protective Eyewear

Protective eyewear is a must when working with an unshielded Nd:YAG laser beam. Several styles of safety glasses and goggles are available. Lenses are made of plastic or glass filtering material. Plastic lenses are lightweight and less expensive than glass lenses. However, glass has better visible transmission. This makes glass lenses more comfortable to wear, and a must for viewing a HeNe alignment laser.

Glasses can be ordered with a corrective prescription, bifocal or no correction. Goggles will fit comfortably over the wearer’s regular prescription glasses.

RF power meter

RF Instruments

RF power meters are used for troubleshooting and tuning RF drivers for Q-switched systems. Various frequency range elements and dummy loads are available.

NeHe laser system

HeNe Lasers

Low power Helium-Neon (HeNe) lasers are often used to assist in the alignment of optical components on Nd:YAG and CO2 lasers. Also, many materials processing lasers employ a HeNe laser beam coaxially with the main laser beam. The coaxial red HeNe spot allows the operator to see exactly where the invisible CO2 or Nd:YAG spot is hitting the workpiece.

Laser Power Probes

Power probes are an inexpensive alternative to power meters. Like a meter, a probe can be used to measure power for operating, troubleshooting or tuning a laser system. However, power probes cannot be used continuously or they will overheat. They are designed for short duration use only and must be allowed to cool between uses. Power probes are lightweight, easy to use and relatively inexpensive.

Power probes are an inexpensive alternative to power meters. Like a meter, a probe can be used to measure power for operating, troubleshooting or tuning a laser system. However, power probes cannot be used continuously or they will overheat. They are designed for short duration use only and must be allowed to cool between uses. Power probes are lightweight, easy to use and relatively inexpensive.

Beam Imaging Equipment

Various types of equipment are available for locating an invisible laser beam and checking its mode. An infrared (IR) viewer is a hand-held device used for locating an invisible laser beam at an optical surface. By looking through the IR Viewer, a technician can see exactly where a laser beam is hitting a mirror. Thermal image plates are used with an ultraviolet lamp for checking and tuning beam mode. A Thermal image plate can be left in the beam path while mirrors and rods are adjusted to obtain the best mode. Various illuminator cards and mode burn paper can be used for quick mode spot checks without the need for an ultraviolet lamp. However, unlike thermal imaging plates, illuminator cards and mode burn paper cannot be left continuously in a laser beam path.

[one_half]

Infrared viewer

[one_half_last]