January 1, 2012

For Immediate Release:

San Jose, CA – Directed Light Inc. has greatly expanded their medical device contract manufacturing operations through their Advanced Technology Job Shop. As more medical device manufacturers outsource production engineering and R&D prototyping; and as parts become smaller and more intricate, laser materials processing has become a critical path to new product development.

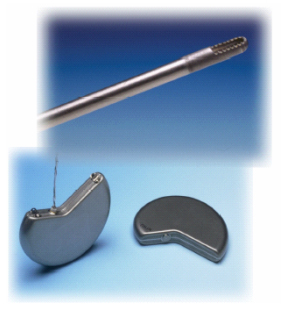

Laser applications in the medical device industry, now provided by Directed Light include laser welding, laser cutting, laser drilling, and laser marking. Laser welding for medical devices allows DLI to hermetically seal very small and intricate components without contacting the device; thus eliminating or tightly controlling distortion due to a much smaller heat-affected zone. This provides a distinct advantage for laser processing over traditional TIG or electron beam welding. Directed Light also provides glove-box welding of implantable medical devices in an inert environment. With laser cutting or drilling, DLI is able to attain feature size to thickness aspect ratios that conventional methods of cutting and drilling cannot attain. This is true for a wide variety of medical grade metals and other biocompatible materials. DLI’s laser marking operations can produce highly precise markings, logos, and/or serialization without contacting the part. Laser welding, cutting, drilling, and marking have proven to be among the medical device engineers’ greatest assets in his or her manufacturing toolbox.

Laser applications in the medical device industry, now provided by Directed Light include laser welding, laser cutting, laser drilling, and laser marking. Laser welding for medical devices allows DLI to hermetically seal very small and intricate components without contacting the device; thus eliminating or tightly controlling distortion due to a much smaller heat-affected zone. This provides a distinct advantage for laser processing over traditional TIG or electron beam welding. Directed Light also provides glove-box welding of implantable medical devices in an inert environment. With laser cutting or drilling, DLI is able to attain feature size to thickness aspect ratios that conventional methods of cutting and drilling cannot attain. This is true for a wide variety of medical grade metals and other biocompatible materials. DLI’s laser marking operations can produce highly precise markings, logos, and/or serialization without contacting the part. Laser welding, cutting, drilling, and marking have proven to be among the medical device engineers’ greatest assets in his or her manufacturing toolbox.

Directed Light is a laser technology company serving the industrial, medical and scientific laser community since 1983. For further information, please call us at 800-468-2326 or visit us online at www.directedlight.com.